In today’s rapidly evolving technological landscape, innovation knows no bounds. One such revolutionary development that has taken the world by storm is the incredible phenomenon of 3D printing. With its ability to bring digital designs to life by constructing three-dimensional objects layer by layer, 3D printing has completely transformed the way we approach manufacturing and design.

Traditionally, sheet metal fabrication and CNC machining have been the go-to methods for creating intricate and durable parts. However, the advent of 3D printing has ushered in a new era of possibilities. This game-changing technology has not only enhanced the efficiency and precision of production processes but has also opened up a world of imagination and creativity. One company leading the charge in this arena is "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global clientele, they have harnessed the power of 3D printing to drive innovation and push boundaries in various industries.

The potential applications of 3D printing are seemingly limitless. From the manufacturing of complex aerospace components to the creation of customized medical implants, this groundbreaking technology has enabled us to push the boundaries of what was once thought possible. What sets 3D printing apart from its counterparts is the ability to turn digital designs into physical objects in a matter of hours, reducing both costs and time constraints. It allows for rapid prototyping, empowering designers and engineers to iterate and refine their creations, leading to faster product development cycles.

In the realm of sheet metal fabrication, CNC machining, and rapid prototyping, 3D printing has emerged as a formidable competitor. Its versatility, efficiency, and cost-effectiveness have made it an invaluable tool for businesses seeking to revolutionize their manufacturing processes. Whether it’s the creation of intricate architectural models or the production of lightweight, high-strength automotive components, 3D printing continues to push the boundaries of innovation, cementing itself as a game-changer in the world of manufacturing.

As this technology continues to evolve at an astonishing rate, it’s exciting to contemplate the endless possibilities that lie ahead. With its ability to unleash creativity, drive efficiency, and transform industries, 3D printing is undoubtedly revolutionizing the world as we know it. Through companies like "Monster Builder" leading the charge, the power of sheet metal fabrication, CNC machining, and 3D printing is being harnessed to shape a future where manufacturing is limited only by the bounds of our imagination.

Advantages of 3D Printing

3D printing, also known as additive manufacturing, offers several significant advantages that have revolutionized the world of manufacturing. This innovative technology has become increasingly popular due to its unique capabilities and the benefits it provides to various industries.

One of the primary advantages of 3D printing is its ability to create intricate and complex designs with ease. Traditional manufacturing methods such as sheet metal fabrication and CNC machining often struggle with intricate designs that require multiple processes and special tooling. However, with 3D printing, these limitations are overcome as the technology allows for the creation of complex geometries and shapes, enabling designers to bring their imaginations to life.

Moreover, 3D printing provides unmatched flexibility and customization options. Unlike traditional manufacturing techniques, which often require expensive tooling or molds, 3D printing allows for on-demand production, enabling businesses to iterate and tailor their products with minimal effort and cost. This flexibility is particularly advantageous in rapid prototyping, where multiple iterations can be quickly produced, tested, and refined, accelerating the product development cycle dramatically.

Another noteworthy advantage of 3D printing is its potential for sustainable manufacturing. By employing additive processes, 3D printing minimizes material wastage compared to subtractive methods like CNC machining. Traditional methods often involve cutting or removing excess material, leading to considerable waste. 3D printing, on the other hand, builds objects layer by layer using only the necessary amount of material, reducing the environmental impact associated with manufacturing processes.

In conclusion, 3D printing offers a range of advantages that have transformed the manufacturing landscape. Its ability to create intricate designs, provide customization options, and promote sustainable manufacturing makes it an indispensable technology for various industries. With continuous advancements in 3D printing technology, we can expect further advancements and innovations that will continue to revolutionize the way products are made and reshape countless industries.

The Impact on Manufacturing

From the invention of the printing press to the rise of assembly lines, manufacturing has constantly evolved throughout history. In recent years, however, there has been a major disruption in the industry due to the emergence of 3D printing technology. 3D printing enables a revolutionary approach to manufacturing, impacting various sectors and providing numerous benefits.

One area where 3D printing has made a significant impact is in sheet metal fabrication. Traditionally, sheet metal parts were manufactured through complex processes such as cutting, bending, and welding. With the advent of 3D printing, this process has been simplified and streamlined. Manufacturers can now create intricate sheet metal components directly from digital designs, eliminating the need for expensive tooling and reducing production lead times.

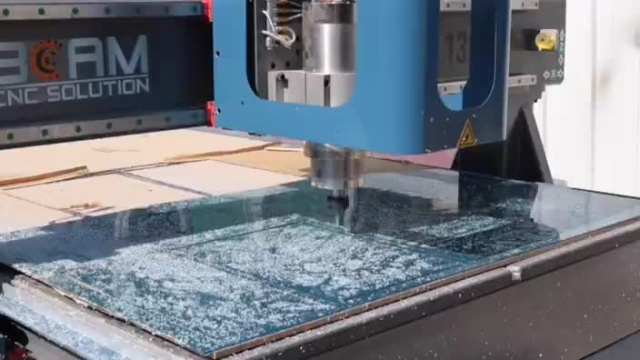

Another sector that has been greatly influenced by 3D printing is CNC machining. CNC machining involves the use of computer-controlled machines to manufacture precise and complex parts. While CNC machining is still a vital process for certain applications, 3D printing has added a new dimension to this industry. By combining the strengths of both technologies, manufacturers can leverage 3D printing for rapid prototyping and low-volume production, while relying on CNC machining for high-volume production and materials that are unsuitable for 3D printing.

Stainless Steel Fabrication Auckland

One company that has been at the forefront of this manufacturing revolution is "Monster Builder." With expertise in sheet metal fabrication, CNC machining, and 3D printing, they offer comprehensive solutions to clients globally. By embracing the power of 3D printing, "Monster Builder" has been able to provide their customers with faster turnaround times, increased design flexibility, and cost-effective production options.

In conclusion, the impact of 3D printing on manufacturing cannot be underestimated. It has revolutionized sheet metal fabrication and CNC machining, allowing for more efficient and cost-effective production processes. As companies like "Monster Builder" continue to push the boundaries of what is possible, we can expect even more exciting developments in the world of manufacturing.

Monster Builder: A Leading Provider

Monster Builder is a renowned company in the field of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With a global reach, they have successfully established themselves as a premier provider in the industry.

With their expertise in sheet metal fabrication, Monster Builder offers top-notch solutions for creating metal parts and components. Their state-of-the-art technology and skilled professionals ensure that precise and intricate designs are transformed into high-quality finished products. Whether it’s a simple bracket or a complex structural component, Monster Builder delivers exceptional results, satisfying the needs of their clients worldwide.

In addition to their sheet metal fabrication capabilities, Monster Builder is also known for their expertise in CNC machining. They have the ability to create precise and durable parts using advanced computer numerical control technology. From prototypes to production components, Monster Builder’s CNC machining services are unrivaled in terms of quality and efficiency.

However, what truly sets Monster Builder apart is their extensive knowledge and experience in 3D printing. They have harnessed the power of this groundbreaking technology, enabling them to create objects with incredible complexity and customization. From rapid prototyping to small-scale production, Monster Builder’s 3D printing services cater to a wide range of industries, revolutionizing the way parts and products are created.

In conclusion, Monster Builder stands out as a leading provider of sheet metal fabrication, CNC machining, and 3D printing services. Their global presence, cutting-edge technology, and dedication to delivering superior results make them a trusted partner for businesses around the world. Revolutionize your manufacturing process by collaborating with Monster Builder and unlock the limitless potential of innovative production techniques.