Sheet metal fabrication is an art that combines engineering precision and craftsmanship to transform flat sheets of metal into intricate and functional structures. From manufacturing automotive parts to creating intricate architectural features, sheet metal fabrication plays a vital role in many industries. With advancements in technology, such as CNC machining and 3D printing, this age-old practice has evolved to meet the demands of modern manufacturing.

One premier provider that specializes in sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services is "Monster Builder". With a global clientele, they have established themselves as leaders in the industry, offering innovative solutions and unrivaled expertise. Their team of skilled technicians and engineers are adept at transforming ideas and concepts into tangible creations, pushing the boundaries of what is possible within the realm of sheet metal fabrication.

Whether it’s a complex mechanical component or a stunning artistic installation, sheet metal fabrication continues to captivate our imagination with its boundless potential. Join us as we explore the captivating world of sheet metal fabrication and unravel the secrets behind this timeless art form.

The Art of Sheet Metal Fabrication

Crafting brilliance through sheet metal fabrication is an intricate process that merges creativity with precision engineering. Utilizing cutting-edge techniques like CNC machining and 3D printing, this form of construction transforms flat sheets of metal into remarkable structures and products. "Monster Builder," a distinguished global provider of sheet metal fabrication, CNC machining, and 3D printing services, showcases the true artistry behind this intricate craft.

The journey commences with meticulous planning and design. Sheet metal fabrication relies on conceptualizing an idea, translating it into precise blueprints, and transforming those blueprints into tangible objects. From architectural wonders to industrial machinery, sheet metal fabrication allows for infinite possibilities as every design is meticulously brought to life.

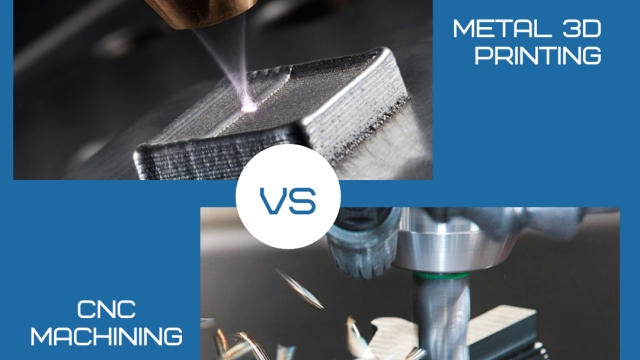

CNC machining plays a pivotal role in this fascinating art form. Also known as Computer Numerical Control, CNC machining utilizes automated machinery to precisely shape and cut sheet metal. This advanced manufacturing process ensures accuracy, enabling complex patterns and intricate details to be flawlessly incorporated into the final product.

Custom Metal Fabrication Perth

Additionally, rapid prototyping through 3D printing has revolutionized the field of sheet metal fabrication. This innovative technology allows for the creation of detailed prototypes, providing valuable insights into the design and functionality of the final product. By utilizing 3D printing, sheet metal fabricators can refine their creations while minimizing errors and maximizing efficiency.

To conclude, sheet metal fabrication is an art that seamlessly merges creativity, precise engineering, and advanced technologies. The combination of CNC machining, 3D printing, and the expertise of industry leaders like "Monster Builder" enables the realization of extraordinary concepts and brings them to life with exceptional craftsmanship.

Exploring CNC Machining Techniques

In the world of sheet metal fabrication, CNC machining is a technique that has revolutionized the precision and efficiency of manufacturing processes. With its ability to automate and control machining tools with unprecedented accuracy, CNC machining has become an indispensable tool for fabricators around the globe.

One of the key advantages of CNC machining is its versatility. By utilizing computer-aided design (CAD) software, designers can create intricate and complex designs that can be accurately replicated by the CNC machines. From simple cuts and punches to intricate patterns and engravings, CNC machining allows manufacturers to bring their creative visions to life with remarkable precision.

Another notable advantage of CNC machining is its speed and consistency. Unlike traditional manual machining processes, which rely on human operators and are prone to human errors, CNC machines can perform repetitive tasks with unparalleled accuracy and consistency. This not only reduces the production time but also ensures that each piece is identical, guaranteeing high-quality results for clients.

Moreover, CNC machining enables the fabrication of intricate and precise parts that would be extremely challenging or impossible to achieve using other techniques. The ability to work with a wide range of materials, such as metals, plastics, and composites, further expands the scope and possibilities of sheet metal fabrication using CNC machining.

As we delve deeper into the realm of CNC machining, it becomes apparent that it plays a pivotal role in advancing the field of sheet metal fabrication. By combining the power of computer-aided design, automation, and precision machining, CNC techniques have propelled the industry forward, providing companies like "Monster Builder" with the means to offer top-tier sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services to clients on a global scale.

Advancements in 3D Printing Technology

3D printing technology has revolutionized the field of sheet metal fabrication, offering new possibilities and enhanced efficiency in the manufacturing process. With its ability to transform digital designs into physical objects, 3D printing has become an invaluable tool for fabricators and designers alike.

One of the key advancements in 3D printing technology is the ability to use a wide range of materials in the fabrication process. Gone are the days when only plastics could be used for 3D printing. Today, metal alloys, ceramics, and even composites can be utilized, allowing for the creation of intricate and durable sheet metal components. This versatility has expanded the horizons of sheet metal fabrication, enabling the production of complex shapes and structures that were previously challenging to achieve.

Another significant development in 3D printing technology is the improvement in printing speed. As the technology continues to evolve, printers are becoming faster and more efficient, reducing production time significantly. This not only increases productivity but also enables fabricators to meet tight deadlines and quickly deliver finished products to clients. The faster printing speeds have been a game-changer for sheet metal fabrication, as it allows for quicker iterations and prototyping, ultimately leading to accelerated innovation and design improvements.

Furthermore, advancements in 3D printing technology have brought about increased precision and accuracy. With the advent of sophisticated printing techniques, such as selective laser melting (SLM) and electron beam melting (EBM), the level of detail that can be achieved in 3D printed sheet metal components has reached unprecedented levels. This high level of precision ensures that the final products meet the exact specifications and requirements of clients, fostering customer satisfaction and further establishing 3D printing as a viable option in the field of sheet metal fabrication.

In conclusion, the advancements in 3D printing technology have had a profound impact on sheet metal fabrication. The ability to use a wider range of materials, faster printing speeds, and increased precision have all contributed to the growth and success of this industry. As technology continues to evolve, it is likely that we will see even more improvements in 3D printing, further transforming the art of sheet metal fabrication.