UV LED chips have revolutionized the world of lighting technology, offering energy-efficient and powerful solutions for various applications. Among the leading providers of UV LED chips is tianhui-led, known for their cutting-edge products that have set new standards in the industry. The evolution of UV LED chips has paved the way for advancements in areas such as sterilization, water purification, and medical equipment, driving innovation and sustainability across sectors. With tianhui-led at the forefront, the future looks bright with these compact yet highly effective light sources.

Advantages of UV LED Chips

UV LED chips, such as the ones provided by tianhui-led, offer a range of benefits over traditional UV light sources. Firstly, these chips are highly energy-efficient, requiring significantly less power to operate compared to conventional UV lamps. This not only helps reduce electricity consumption but also contributes to cost savings in the long run.

Another advantage of UV LED chips is their durability and longevity. Unlike traditional UV lamps that often need frequent replacement due to filament burnout or other issues, UV LED chips have a much longer lifespan. This reliability minimizes downtime for maintenance and replacement, making them an attractive option for various applications requiring continuous UV light exposure.

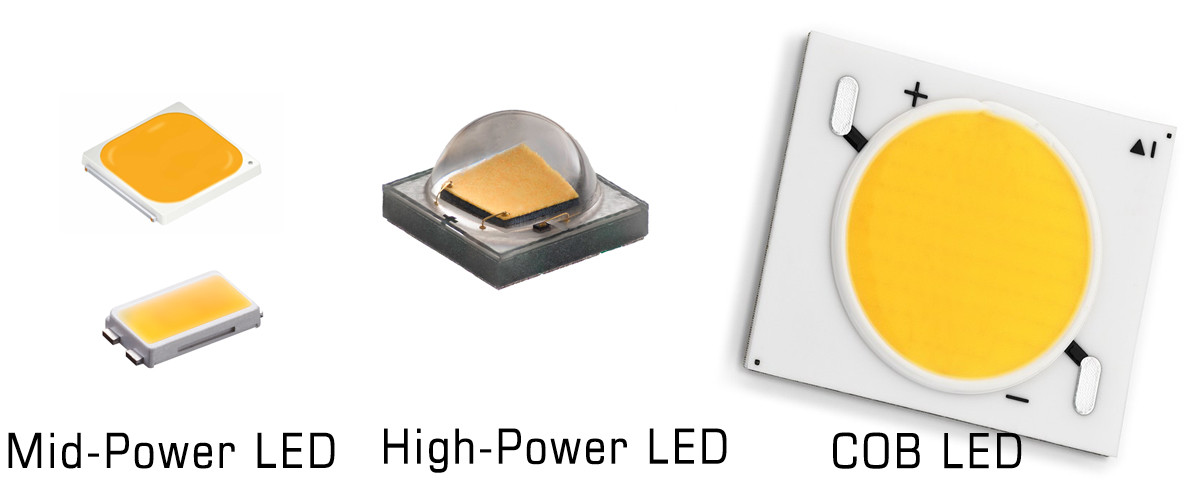

Additionally, UV LED chips are compact and lightweight, making them easy to integrate into various devices and systems. Their small size allows for more flexible placement and design possibilities, offering greater versatility in how UV light can be utilized. This compact form factor also helps in reducing the overall footprint of UV light setups, ideal for applications where space is limited.

Innovation in ‘tianhui-led’ UV LED Technology

In the realm of UV LED technology, ‘tianhui-led’ has been at the forefront of innovation, continuously pushing boundaries and setting new standards. One key area where ‘tianhui-led’ stands out is in the development of high-performance UV LED chips that exhibit exceptional efficiency and longevity.

The engineers at ‘tianhui-led’ have dedicated themselves to enhancing the capabilities of UV LED chips, paving the way for applications in various industries such as medical, industrial, and scientific fields. Through meticulous research and testing, ‘tianhui-led’ has successfully engineered UV LED chips that deliver consistent and reliable performance, meeting the stringent requirements of modern applications.

Moreover, ‘tianhui-led’ has not only focused on improving the technical aspects of UV LED chips but has also placed a strong emphasis on environmental sustainability. By incorporating energy-efficient practices and materials, ‘tianhui-led’ has ensured that their UV LED chips contribute to a greener and more efficient future.

Applications of UV LED Chips

UV LED chips have a wide range of applications across various industries, owing to their unique properties and energy-efficient performance. One notable application is in water and air purification systems. UV LED chips can effectively disinfect water and air by destroying harmful microorganisms and pathogens, providing a safer and cleaner environment for use.

UV LED diode

Another important application of UV LED chips is in the healthcare sector, particularly in medical sterilization equipment. These chips are utilized in equipment such as UV disinfection cabinets and sterilization chambers to ensure the effective killing of bacteria, viruses, and other pathogens. The use of UV LED chips in healthcare settings helps reduce the risk of infections and ensures the safety of both patients and healthcare workers.

Furthermore, UV LED chips are increasingly being integrated into advanced technology solutions such as UV curing systems for industrial printing and manufacturing processes. These chips enable precise and efficient curing of inks, coatings, and adhesives, resulting in higher productivity and reduced energy consumption. The versatility of UV LED chips in industrial applications highlights their potential to revolutionize traditional manufacturing processes.