Stretching the Limits: Unveiling the Power of the Stretch Wrapper

In today’s fast-paced business environment, efficiency is key. When it comes to warehouse logistics, finding ways to streamline operations can significantly impact productivity and ultimately, the bottom line. Enter the stretch wrapper – a pallet wrapping machine that has become an indispensable tool in modern-day material handling.

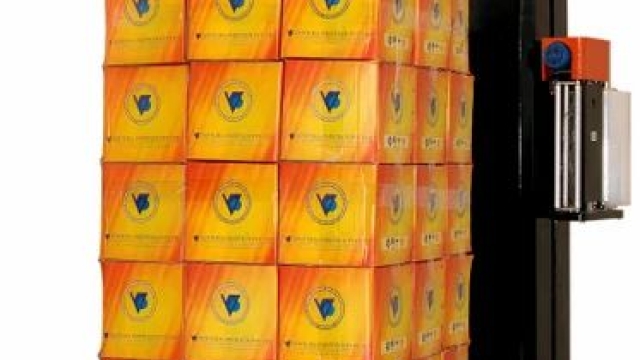

The stretch wrapper, also known as a pallet wrapper or stretch wrap machine, is designed to securely package goods on pallets for storage, transportation, and distribution. With its ability to tightly wrap stretch film around the pallet, this innovative technology provides an effective solution to safeguard products from damage, minimize loss, and optimize load stability.

By using a stretch wrapper, businesses can achieve several advantages. Firstly, it enhances the protection of goods during transit, reducing the risk of product damage caused by shifting loads or external factors such as moisture or dust. Additionally, the secure wrapping provided by the machine acts as a theft deterrent, ensuring products arrive intact at their intended destination.

Furthermore, the stretch wrapper streamlines the loading and unloading process. With automated features, such as pre-set wrapping programs and adjustable settings to accommodate different load sizes, it simplifies and expedites the packaging process. This not only saves time but also reduces labor costs by eliminating the need for manual wrapping, allowing employees to focus on other critical tasks.

As companies strive to optimize their supply chain operations, the stretch wrapper proves to be an invaluable asset. Its ability to improve efficiency, protect goods, and ensure safer transportation all contribute to a more streamlined and reliable logistics process. With the power of the stretch wrapper, businesses can stretch their limits and meet the demands of the ever-evolving marketplace.

Benefits of Using a Pallet Wrapper

Using a Pallet Wrapper, also known as a stretch wrapper or stretch wrap machine, offers several advantages in the packaging and logistics industry. Here are three key benefits:

Enhanced Stability and Protection: The primary advantage of utilizing a pallet wrapper is the ability to provide enhanced stability and protection to the wrapped goods. The stretch film applied by the machine tightly secures the items to the pallet, preventing any unnecessary movement or shifting during transit. This significantly reduces the risk of damage, such as breakage or product loss, which can result in costly setbacks and customer dissatisfaction.

Shrink Wrap MachineTime and Labor Efficiency: Manual pallet wrapping can be time-consuming and physically demanding. However, with the introduction of pallet wrappers, the process has become more efficient and less labor-intensive. These machines automate the wrapping procedure, saving valuable time and reducing the strain on workers. By eliminating the need for manual labor, businesses can allocate their resources to other critical tasks, ultimately enhancing overall productivity.

Cost Savings: Pallet wrappers contribute to cost savings in multiple ways. Firstly, they facilitate consistent and optimized film usage, minimizing the waste of wrapping material. This not only reduces expenses related to film purchases but also promotes sustainability by minimizing environmental impact. Additionally, the enhanced stability provided by the machine reduces the potential for product damage, helping businesses avoid costly returns or replacements. Moreover, the time saved by automating the process translates to improved operational efficiency and potential cost reductions in the long run.

In summary, the utilization of a pallet wrapper offers benefits such as enhanced stability and protection, improved time and labor efficiency, and cost savings. By leveraging these advantages, businesses can streamline their packaging processes, optimize resources, and ensure the safe transportation of goods.

Key Features to Consider

When choosing a stretch wrapper for your packaging needs, it is important to consider several key features that will ensure efficiency and effectiveness in your pallet wrapping process.

Pallet Wrapping Machine: Look for a stretch wrapper that is specifically designed for pallet wrapping. These machines are equipped with the necessary features and capabilities to handle pallets of various sizes and weights. A dedicated pallet wrapping machine ensures that the wrapping process is optimized for the specific requirements of palletized loads.

Stretch Wrap Machine: With advancements in technology, stretch wrap machines have become more sophisticated and versatile. Consider a stretch wrap machine that offers adjustable tension control, allowing you to customize the amount of stretch applied to the film. This feature enables you to achieve the desired level of load stability while reducing the risk of product damage during transportation.

User-Friendly Interface: Ease of use is a crucial factor when selecting a stretch wrapper. Look for a machine with a user-friendly interface that simplifies the operation and minimizes the training time required for your employees. An intuitive control panel and clear instructions can ensure smooth and efficient pallet wrapping, even for operators with limited experience.

By considering these key features – a dedicated pallet wrapping machine, an advanced stretch wrap machine, and a user-friendly interface – you can select a stretch wrapper that maximizes efficiency, product protection, and overall satisfaction in your packaging process.

Tips for Efficient Stretch Wrapping

To maximize the efficiency of your stretch wrapping process, consider the following tips:

Load Securely: Ensure that your pallets are stable and properly positioned before starting the stretch wrapping process. This will help prevent any movement or damage during transit. Additionally, make sure to evenly distribute the weight on the pallet to maintain balance.

Select the Right Film: Choosing the correct stretch film is crucial for ensuring optimal load containment. Consider factors such as the type of goods being wrapped, their dimensions, and the expected transport conditions. Select a film with appropriate thickness and stretch capabilities to avoid overstretching or insufficient containment.

Adjust Parameters Properly: Take the time to fine-tune the settings of your stretch wrapper to match the specific requirements of your load. This includes adjusting the tension, pre-stretch, and number of rotations to achieve the desired level of stability. Regularly monitor and calibrate these parameters to consistently achieve efficient results.

By implementing these tips, you can enhance the efficiency of your stretch wrapping process and ensure that your goods arrive at their destination securely and intact. Proper loading, selecting the right film, and adjusting parameters are key elements to consider for successful pallet wrapping.

Keep in mind that each application may have its unique requirements, so it is important to regularly evaluate and optimize your stretch wrapping process accordingly.