Industrial valves are at the heart of countless operations across a wide range of industries. These powerful devices play a vital role in controlling the flow of liquids, gases, and other substances, making them essential components in everything from manufacturing and oil refining to water treatment and energy production. With their ability to regulate, isolate, and direct the flow within pipelines, industrial valves have revolutionized the way operations are conducted in various sectors.

One type of industrial valve that has proven to be particularly versatile is the wedge gate valve. Designed to provide excellent sealing capabilities, the wedge gate valve is commonly used in applications where a tight shut-off is required. Its robust construction and reliable performance make it ideal for use in water treatment plants, oil and gas facilities, power generation plants, and other demanding environments. With its simple yet effective design, this valve has become a cornerstone of many industrial processes.

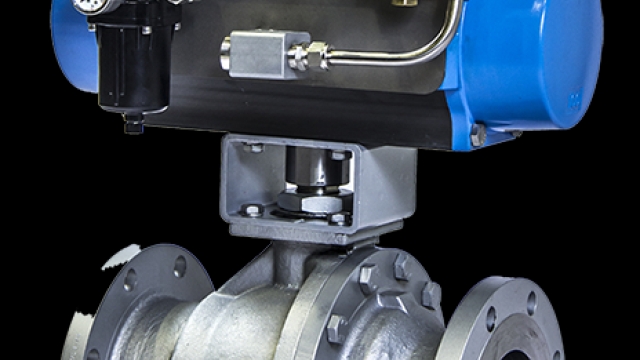

Another noteworthy type of industrial valve is the flanged gate valve. Renowned for its durability and strength, the flanged gate valve is a popular choice for applications that involve high-pressure and high-temperature environments. This valve is equipped with flanges that allow for easy installation and removal, making maintenance and repair tasks more efficient. Its ability to handle challenging conditions makes it indispensable across a wide range of industries, including chemical processing, mining, and wastewater management.

The water gate valve is yet another crucial variant in the realm of industrial valves. Having the ability to regulate the flow of water, this valve is widely used in municipal water distribution systems, irrigation networks, and fire prevention systems. Its reliable performance, combined with its ease of operation and maintenance, has made the water gate valve an integral part of ensuring the smooth flow and control of water in various settings.

Additionally, the cast iron gate valve holds significant importance within industries that require a reliable and cost-effective solution for controlling fluid flow. Made from sturdy cast iron material, this valve possesses excellent corrosion resistance and durability, allowing for a longer service life. It is commonly utilized in water supply systems, wastewater treatment plants, and industrial processes where a strong, resilient valve is necessary.

Industrial valves, such as the wedge gate valve, flanged gate valve, water gate valve, and cast iron gate valve, have undoubtedly revolutionized operations across numerous industries. By offering reliable control and regulation of fluids, these valves contribute to increased productivity, enhanced safety, and improved efficiency in a wide array of applications. As industries continue to evolve, so too will the vital role played by industrial valves in facilitating smooth and seamless operations.

Types of Industrial Valves

Valves play a vital role in various industries, enabling the controlled flow of liquids, gases, and other media. Industrial valves come in different types, each designed to meet specific operational needs and requirements. Let’s explore some of the common types of industrial valves used across industries.

Wedge Gate Valve:

The wedge gate valve is widely used in industrial applications where a straight-line flow of fluid and minimal pressure drop is required. This type of valve features a gate or wedge-shaped disk that controls the flow by either fully opening or closing the passage. Its solid construction and ability to handle high pressures and temperatures make it suitable for demanding environments.Flanged Gate Valve:

The flanged gate valve is specifically designed for use in high-pressure systems. It features flanges on both ends, allowing for easy installation between pipes or fittings. This valve design offers excellent sealing capabilities and provides reliable shut-off control. With its sturdy construction and resistance to corrosion, the flanged gate valve is a preferred choice in various industries.Water Gate Valve:

As the name suggests, water gate valves are primarily used for water applications, such as water distribution networks and water treatment plants. These valves are designed to regulate the flow of water efficiently. With their excellent sealing ability and robust construction, water gate valves ensure reliable and long-lasting performance in water-related operations.Cast Iron Gate Valve:

The cast iron gate valve is known for its durability and strength, making it suitable for heavy-duty industrial applications. This valve is designed with a cast iron body, ensuring its capability to withstand high pressures and harsh environments. Its reliable performance, cost-effectiveness, and easy maintenance make it a popular choice in industries such as oil and gas, power generation, and wastewater management.

By understanding the different types of industrial valves available, industries can choose the most suitable valve for their specific operational requirements. Whether it’s optimizing flow control, ensuring safety, or improving efficiency, industrial valves are indeed revolutionizing operations across various sectors.

2. Key Features and Applications

In this section, we will explore the key features and applications of industrial valves. Industrial valves play a crucial role in various industries, facilitating the regulation and control of fluids and gases within pipelines and systems. Let’s take a closer look at some of the notable features and applications of industrial valves.

Industrial Valves

Wedge Gate Valve

The wedge gate valve is a widely used type of industrial valve. It is designed with a wedge-shaped gate that moves up and down to control the flow of fluids. One of the key features of the wedge gate valve is its ability to provide a tight and reliable sealing, minimizing leakage. This makes it suitable for applications where a high degree of isolation and flow control is required, such as in oil and gas pipelines, water supply systems, and power plants.Flanged Gate Valve

Another commonly utilized industrial valve is the flanged gate valve. It is characterized by its flanged ends, which allow for easy installation and connection to pipelines. The flanged gate valve is often employed in industries that deal with corrosive or abrasive fluids, thanks to its robust construction and durability. It finds its applications in chemical processing plants, wastewater treatment facilities, and mining operations, among others.Water Gate Valve

The water gate valve, as the name suggests, is specifically designed for regulating the flow of water. It features a resilient seat and a rising spindle that lifts the gate to allow or restrict the passage of water. This type of valve is commonly found in water distribution systems, irrigation networks, and firefighting installations. Its reliable performance and ability to handle high water pressures make it an indispensable component in these applications.Cast Iron Gate Valve

The cast iron gate valve is a versatile valve used in a wide range of industries. Its notable feature is its cast iron body, which provides excellent strength and resistance to corrosion. This type of valve is suitable for handling various fluids, including water, oil, gas, and even steam. Its applications span across industries such as HVAC systems, chemical manufacturing, water treatment plants, and more.

Industrial valves are crucial components in the efficient operation of pipelines and systems in various industries. The wedge gate valve, flanged gate valve, water gate valve, and cast iron gate valve are just some of the many types available, each designed to meet specific application requirements. By understanding their features and applications, industries can unlock the immense power that industrial valves bring, revolutionizing their operations and ensuring optimal performance.

3. Advantages of Industrial Valves

Industrial valves offer several significant advantages in various industries. Their versatility and functionality make them essential components for efficient operations. Here are three key advantages of industrial valves:

Enhanced Flow Control: Industrial valves, such as the wedge gate valve, flanged gate valve, and water gate valve, enable precise control of fluid flow. These valves are designed to regulate the passage of liquids, gases, and even slurries. With the capability to adjust the flow rate effectively, industrial valves ensure optimal system performance and prevent any potential disruptions.

Reliable Shut-off Capability: Another advantage of industrial valves is their reliable shut-off capability. The cast iron gate valve, for instance, is well-known for its ability to provide a tight seal, completely blocking the flow of fluids when necessary. This feature is particularly crucial during maintenance or emergencies, as it allows operators to isolate specific sections of a pipeline without disrupting the entire system.

Durability and Longevity: Industrial valves are built to withstand demanding conditions and deliver long-lasting performance. Constructed from robust materials like cast iron, stainless steel, or brass, these valves exhibit excellent durability and resilience. They can withstand high temperatures, pressure differentials, and corrosive environments, ensuring their reliability even in harsh operating conditions.

By harnessing the power of industrial valves, industries can achieve improved flow control, dependable shut-off capabilities, and long-lasting performance, ultimately revolutionizing their operations across various sectors.